Our On Track series explores what levers we can pull to reduce the environmental impact of building structures. The need to accelerate climate action in the form of innovative solutions that minimize both operational and embodied carbon is imperative and represents a critical part of a low-carbon future. Last month focused on policy and embodied carbon and this month focuses on the embodied carbon impact of transfer structures in buildings.

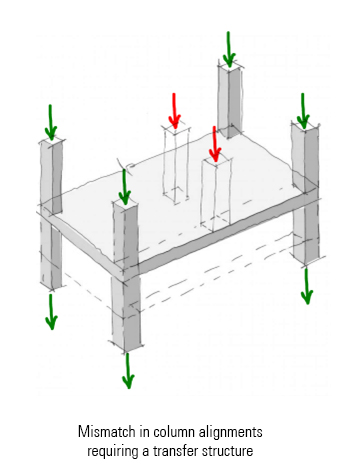

We recognize transfers can be a necessary evil. There are several reasons a project may need to introduce a transfer.

Here is a brief, albeit non-exhaustive, list:

- The columns we strategically placed in the closets on the residential levels land right in the middle of the CRU space at the ground floor, or even worse, the middle of the drive-aisle or loading bay;

- The parking grid needs a 3-stall spacing for maximum efficiency, but we can’t carry that spacing up through the tower and achieve a thin structural assembly;

- Setback and clearance requirements push the massing in away from the basement walls and force us to perform structural “acrobatics”;

- Residential unit plans don’t stack floor to floor. The list goes on…

For the reasons noted above, a transfer may be unavoidable but it is best to evaluate all options before jumping to the infamous transfer solution. It’s amazing what can be achieved with a little extra planning in the early stages of a project! As engineers, we consider all the options to avoid a transfer, which is why we may sound like a broken record on project calls when we ask, “Are you sure we can’t shift the loading bay or make the drive-aisle and entry ramp stack?” While this process may require additional coordination, especially if the project has already advanced and works on paper, we’ve seen the benefit and think it’s worth it – here is why!

Carbon Impact of Transfer Slabs

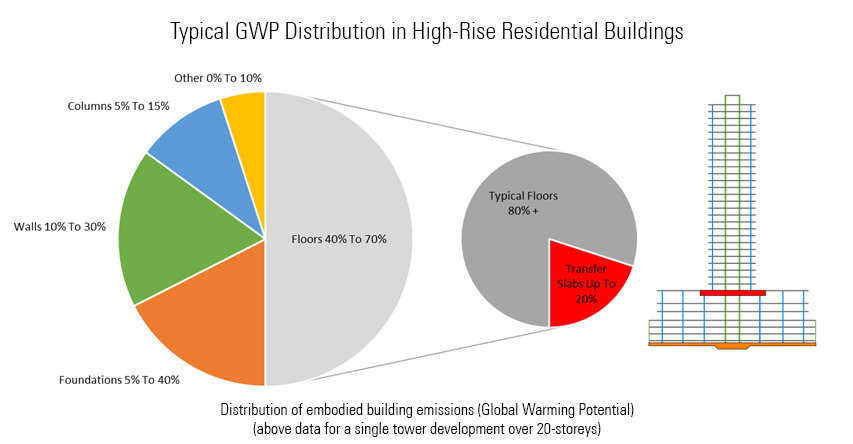

How impactful are transfer slabs on the building’s GWP?

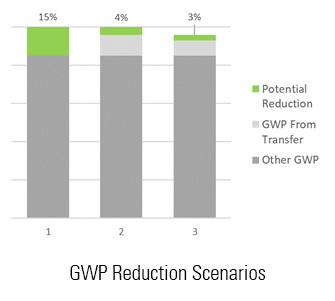

Transfer structures are a significant source of embodied carbon in buildings. Although they often represent a small proportion of a building’s total floor area (typically less than 5%), they are a substantial contributor of a building’s total GWP and can contribute up to 15% of the entire building structure’s embodied carbon.

For projects of this scale, even single percentile reductions in total GWP can result in hundreds of tonnes of CO2e emissions averted.

How can you reduce the GWP impact of transfer structures?

GS suggests three main strategies for reducing a building’s embodied carbon when considering transfer structures, listed from most impactful to least impactful:

1. In the preliminary stages, layout a building to reduce or avoid transfers entirely.

1. In the preliminary stages, layout a building to reduce or avoid transfers entirely.

2. Design with the intention of adopting a one-way beam system as opposed to using two-way slabs.

3. Optimizing the design of a transfer structure to minimise embodied carbon for a given capacity.

Avoiding Transfers

A building structure’s total embodied carbon can be reduced by up to 15% by simply adjusting a building layout to avoid transfers entirely. We see transfer levels commonly between two distinct building functions or occupancy, but a well-thought out layout can continue through the full height of a building. There are many cities and markets where this strategy is common, if not standard.

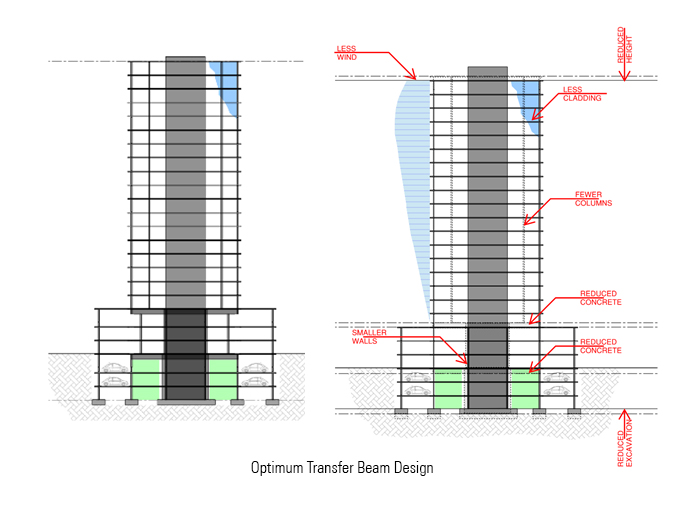

Although this may sometimes be challenging to accommodate when considering architectural and marketing constraints, there are significant additional benefits that allow this compromise to be worthwhile:

1. Building regularity significantly improves:

- Material efficiency

- Construction efficiency

- Building resiliency

2. Post-tensioned slabs can be used to achieve larger grid spans resulting in further efficiencies of floor slabs. This also results in a significantly lighter building.

3. Reduced building mass reduces building loads which:

- Reduces column loads/sizes

- Reduces footing loads/sizes

- Reduces excavation requirements

The full scope of material reductions and embodied carbon reductions associated with the use of PT slabs in lieu of mild steel, rebar slabs, and its benefits to the architectural space will be explored in our June issue.

These result in additional GWP reductions across the rest of the structure.

One-Way Transfers

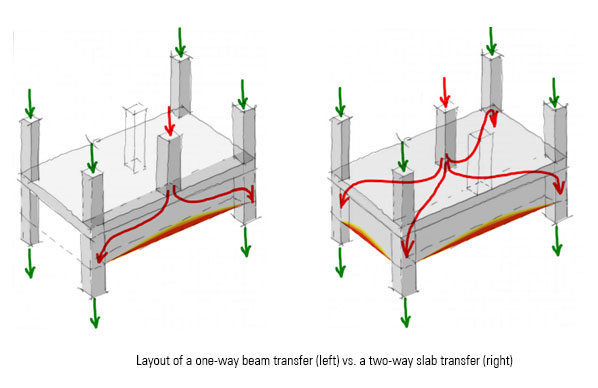

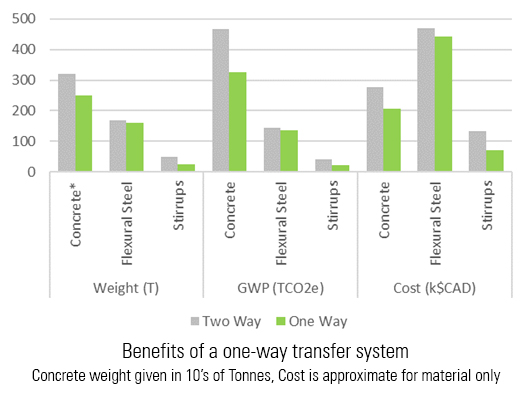

When transfer structures cannot be avoided due to building layout constraints, it is generally better to consider a series of transfer beams (one-way system) as opposed to transfer slabs (two-way system) to discretize the transfer of load to more concentrated but less extensive elements.

When transfer structures cannot be avoided due to building layout constraints, it is generally better to consider a series of transfer beams (one-way system) as opposed to transfer slabs (two-way system) to discretize the transfer of load to more concentrated but less extensive elements.

Through a thorough analysis of previous projects, we have realized reductions in GWP of approximately 25% in a fully designed beam transfer system when compared to a fully designed slab transfer system.

Efficient coordination among various consultants, particularly architectural and structural, during the initial design phase is key to creating a well-designed beam transfer system. Despite having minimal impact on the architectural layout and functionality of the building, this careful assessment and coordination, aimed at meeting both architectural and structural requirements, is worthwhile due to the resulting reduction in embodied carbon.

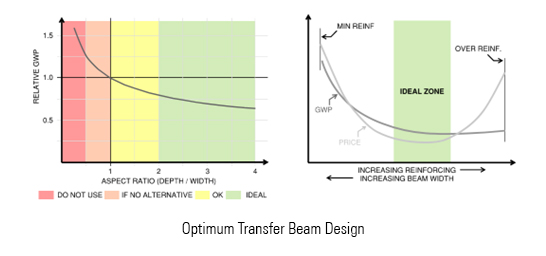

Designing beams to minimize GWP

While project constraints may sometimes limit the adoption of the most economical beam section, there are guidelines that can be implemented for reducing GWP:

- Maximise depth as much as possible (high-aspect ratio)

- Use lower MPa concrete

- Adjust width for “ideal zone”

For shear governed beams, a very similar approach can also be adopted.

For shear governed beams, a very similar approach can also be adopted.

Interested in sustainable building design and how we can help reduce embodied carbon in complex structural designs? Get in touch with us at info@GlotmanSimpson.com

Together, we can contribute to a more sustainable built environment.

Written by Rory Roberts