![]()

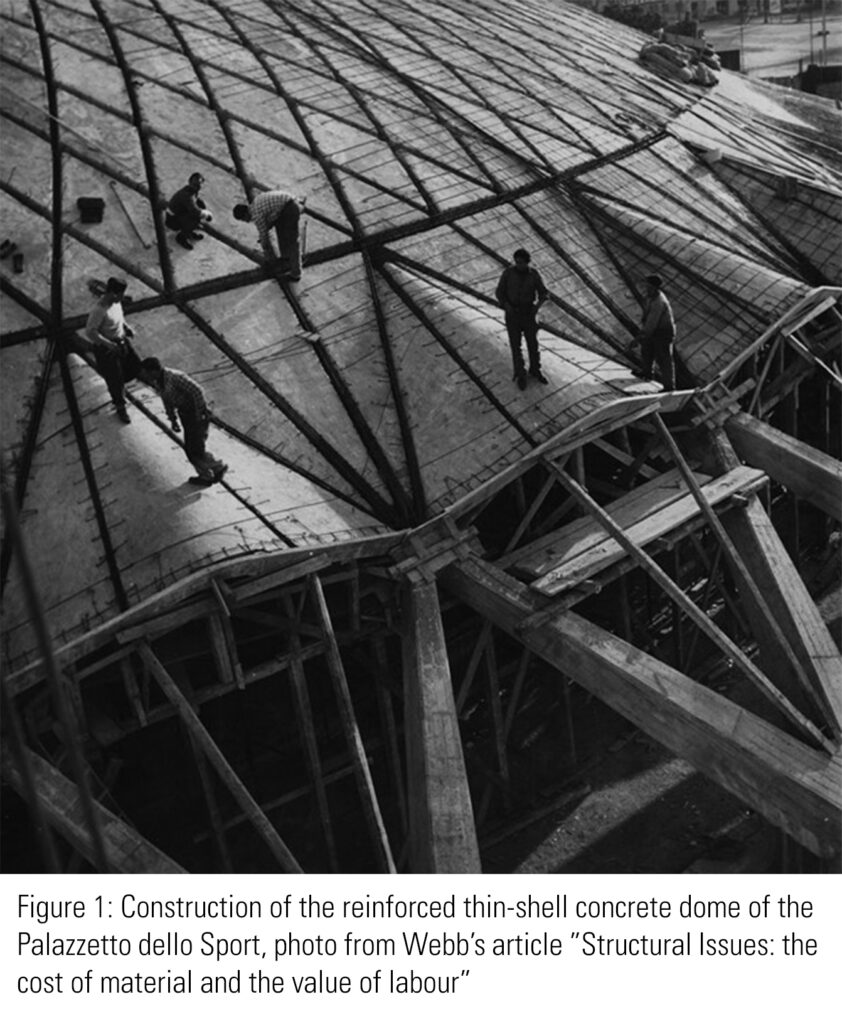

We recently stumbled upon a thought-provoking article, authored by Steve Webb, in The Architectural Review. Webb envisions an alternative future where taxes are employed to protect human labour and penalize excessive material use, thus curbing wasteful practices. Historically, the cost of labour has outweighed the price of materials, resulting in buildings designed to minimize labour by favouring repetition and standardization, albeit at the expense of material waste.

Webb claims that “a building is 30 percent heavier than it needs to be due to labour-saving rationalization.” While we take pride in designing our buildings to be far less wasteful, it is undeniable that a delicate balance between optimizing material and labour persists. For instance, we might replace discrete transfer beams with a transfer slab to reduce formwork or utilize uniform steel beam sections and connections designed to match the beam’s properties. We may also categorize together columns and footings with similar demands to simplify site management and rebar placement. Simplifying our drawings and design is essential to construction, but it may result in material waste.

“As the balance between labour and material costs continue to shift, how will this change our behaviour and design approach?”

In 2021 and 2022, we witnessed unprecedented increases in material costs, including wood, structural steel, concrete, and rebar. Although these commodity prices appear to be stabilizing or decreasing, taxes or penalties on these materials are set to rise. In our recent series, we delved into the embodied carbon policies implemented in Vancouver and California. These regulations represent just the beginning of efforts to achieve net-zero emissions by 2050.

On the labour front, increased automation, prefabrication, and modular construction have enabled us to achieve more with less on-site. Advanced modeling software allows us to collaborate with contractors and other disciplines to resolve complex issues before breaking ground.

As the balance between labour and material costs continues to shift, how will this change our behavior and design approach? It would be naive to assume that employing high-performance concrete or low-carbon steel alone will suffice to meet these ambitious material reduction targets. To reach our lofty embodied carbon reduction goals, we must fundamentally rethink our structural systems.

“We can draw inspiration from old-fashioned, yet materially efficient systems that were phased out due to their labour-intensive nature.”

Steve Webb’s article mentions a more optimistic era when architects and engineers constructed highly efficient web-like structures or thin-shell designs. While these iconic works of Felix Candela and Eladio Dieste are beautiful, they are far from commonplace. Building with mass timber presents another attractive option to reduce embodied carbon, and we’re enthusiastic about working on numerous such projects, including M5 and 843 N. Spring. However, we acknowledge that not every building can be constructed from mass timber or thin-shell concrete elements.

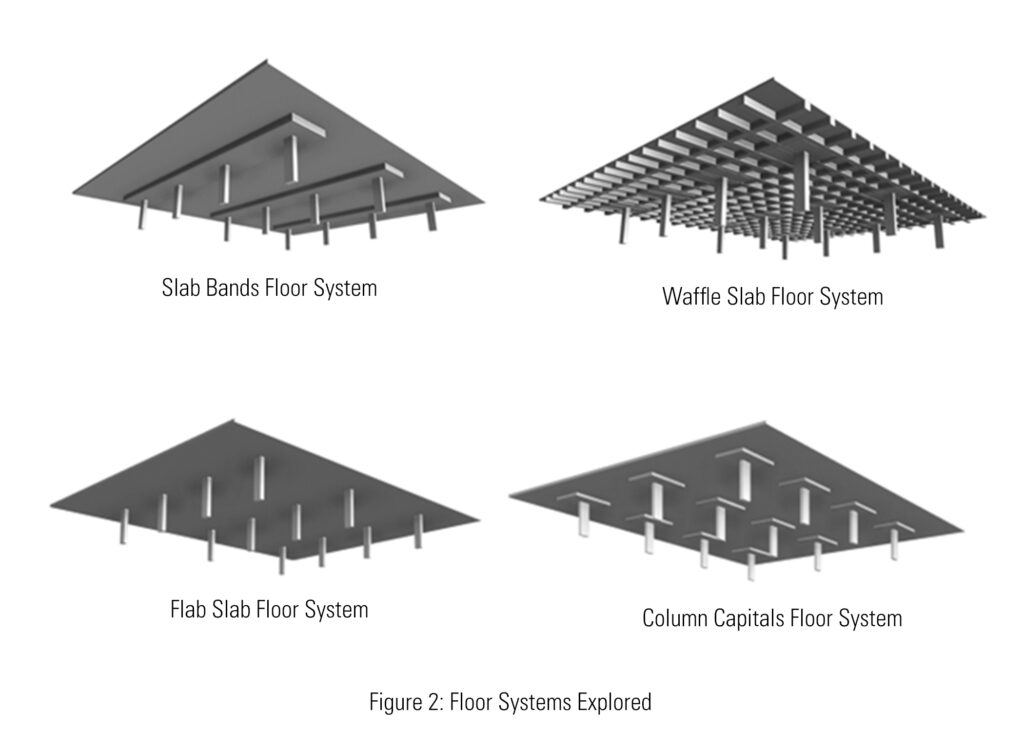

We can certainly draw inspiration from old-fashioned, yet materially efficient systems that were phased out due to their labour-intensive nature. For example, take a stroll around most parking structures built in the ’70s or ’80s, and you’ll likely find prefabricated waffle systems or cast-in-place slab band systems. Our work upgrading old buildings has given us the chance to rediscover, and draw inspiration from, detailed sketches of carefully crafted column capitals. In this month’s series, we explore how these systems can be readily implemented on many of our projects to make a meaningful impact and immediately drive reductions.

Like fashion trends that cycle in and out, we may see the resurgence of old structural systems.

To better understand the embodied carbon impact of these systems, we modeled a typical parking structure and designed various systems to meet the same strength and deflection requirements.

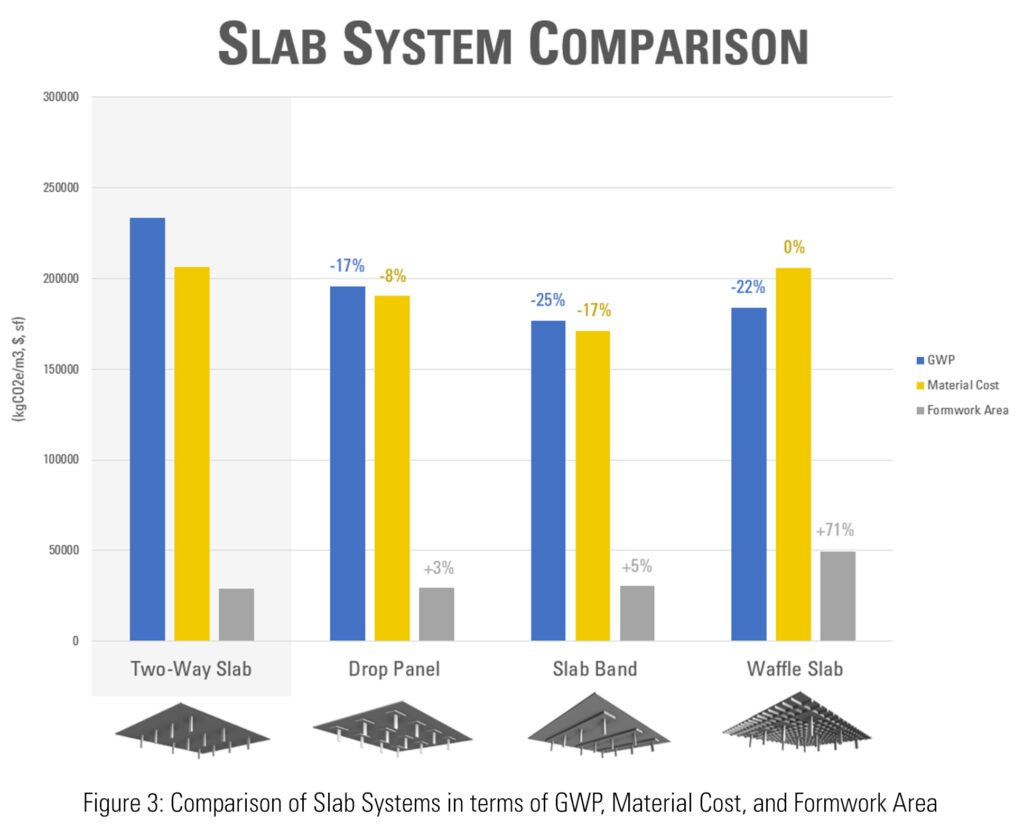

For ease of construction, the 10” thick flat slab, depicted in Figure 2 is most common for parking slab construction. Aligned with the article’s premise, “heavy ‘flat slabs’ proliferate while thin shells or waffles are rare”. We compared the Global Warming Potential (GWP), material cost and required formwork area of three alternative slab construction types shown in Figure 2 against typical flat slab construction.

Assuming industry baseline EPDs for concrete and rebar, alongside current standard rates, we observe a 25% reduction in Global Warming Potential (GWP) with a slab band system, followed by 22% and 17% reductions with the waffle slab and drop panels, respectively. Moreover, material costs decrease by 17% and 8% for the slab band and drop panel systems, while the waffle slab remains similar due to reinforcing densities. The formwork area for the waffle system is substantially higher, but the formwork for the drop panel and slab band systems are marginally so.

Considering these factors, why not consider incorporating slab bands into all our parking structures tomorrow? While they may require a bit more labour, what if we could leverage automation and prefabrication to offset these labour costs? As we actively seek sustainable solutions to meet embodied carbon targets, what other systems can we explore to make significant strides in reducing embodied carbon?

Interested in sustainable building design and how we can help reduce embodied carbon in complex structural designs? Get in touch with us at info@GlotmanSimpson.com.

Written by Harrison Glotman, Marcus Monk + Rachelle Habchi

Glotman Simpson’s On Track series delves into factors we can explore to reduce the environmental impact of building structures. The need to accelerate climate action in the form of innovative solutions that minimize both operational and embodied carbon is imperative and represents a critical part of a low-carbon future.