Footing Elements + Sustainability

Footings are the unsung heroes of building structures, performing a vital role without attracting attention. Unlike the prominent architectural features of ever-popular Mass Timber structures or the aesthetically rustic steel braces systems often found in retrofit buildings, footings are often buried below a layer of soil and then further covered by a slab-on-grade. Despite all of that, footings fulfill their critical function day in and day out: providing unwavering support to an entire building (and with no complaints either).

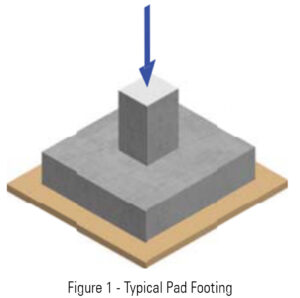

Footings transfer vertical load from the building above to the soil below by spreading out the load and reducing the pressure at the soil-structure interface. There are many different types of footings and the particular ones chosen for a building depends on the soil quality and geological strata at a given site. Pad footings, pile foundations and mat foundations are the most common types designed in our office.

Footings transfer vertical load from the building above to the soil below by spreading out the load and reducing the pressure at the soil-structure interface. There are many different types of footings and the particular ones chosen for a building depends on the soil quality and geological strata at a given site. Pad footings, pile foundations and mat foundations are the most common types designed in our office.

In most of Metro Vancouver, the soil is strong, allowing for columns to be supported on an isolated footing separate from other columns. These are also known as pad footings and will be the focus of this month’s study.

Impact of Foundation Elements on a Building’s Global Warming Potential (GWP)

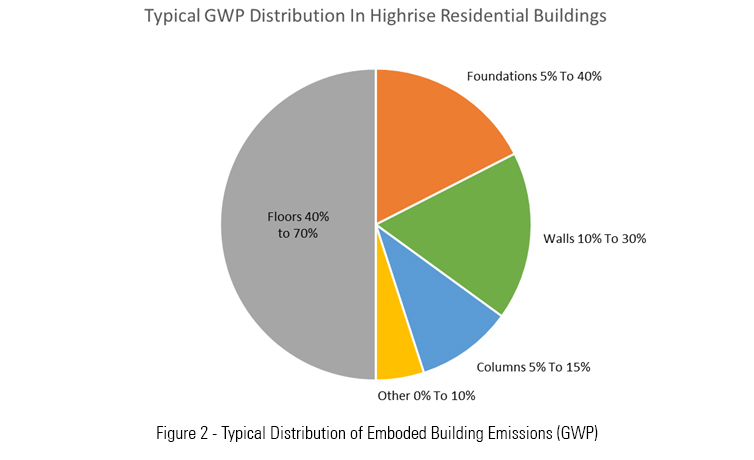

Although hidden, footings account for a large percentage of the GWP in a building; this depends on factors such as the type of footing used and the quality of the soil at the project site.

Because footings are buried, this is the rare occasion in which Structural Engineers are given free rein to design the most efficient structure with minimal constraints. Aside from getting in the way of a few pipes, we are rarely challenged with the inevitable questions that tend to manifest on every project (“How small can it be? Are we able to thin it out or eliminate it altogether?”) when designing footings. With this freedom, we have made it our mission to solve for the most cost-effective, structurally efficient, and sustainable pad footing – glamorous, we know!

Historical Pad Footing Design Approach

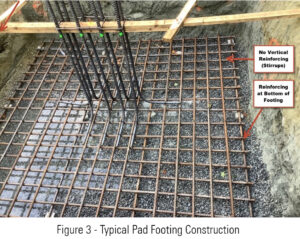

Historically, pad footings have been designed as large pads of concrete with longitudinal reinforcing only on the bottom and no stirrups which are the vertical reinforcing bars intended to resist shear. The historical practice of providing no vertical/shear reinforcement was to keep construction simple and cost down as it is less reinforcing overall, and labour compared to a footing with vertical/shear reinforcing.

Historically, pad footings have been designed as large pads of concrete with longitudinal reinforcing only on the bottom and no stirrups which are the vertical reinforcing bars intended to resist shear. The historical practice of providing no vertical/shear reinforcement was to keep construction simple and cost down as it is less reinforcing overall, and labour compared to a footing with vertical/shear reinforcing.

Pad Footing Optimization

The plan area of a footing is dependent only on the column load and the bearing capacity (measure of the soil’s ability to resist weight) as provided by the geotechnical engineer. As Structural Engineers, we can minimize the GWP of our footings by doing the following:

1. Adjust the concrete strength and subsequent thickness of the pad footing.

2. Change design approach to include design with shear reinforcing.

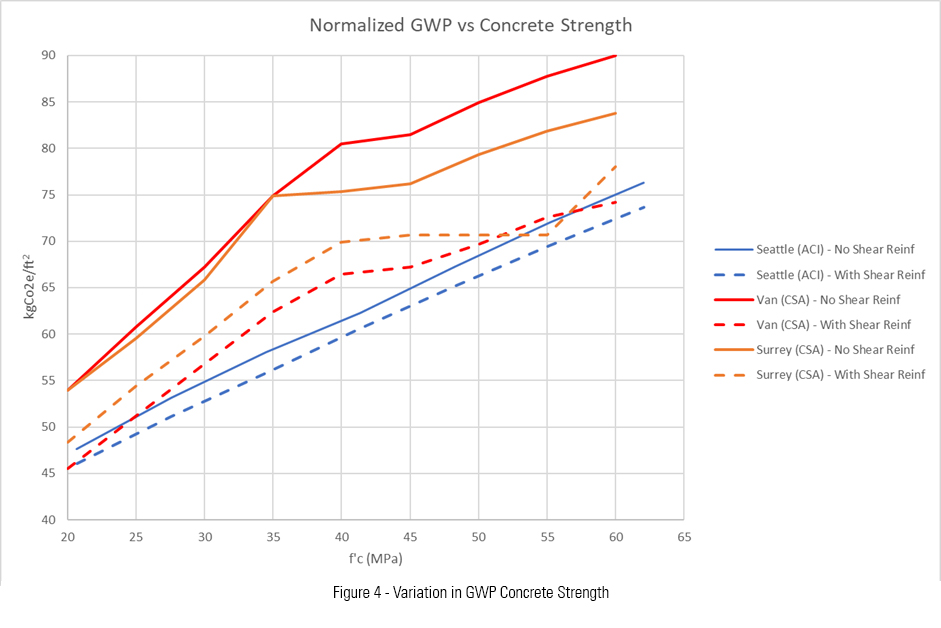

To understand the impact of each of these levers, we looked at footing designs with varied soil types in Vancouver, Surrey, and Seattle.

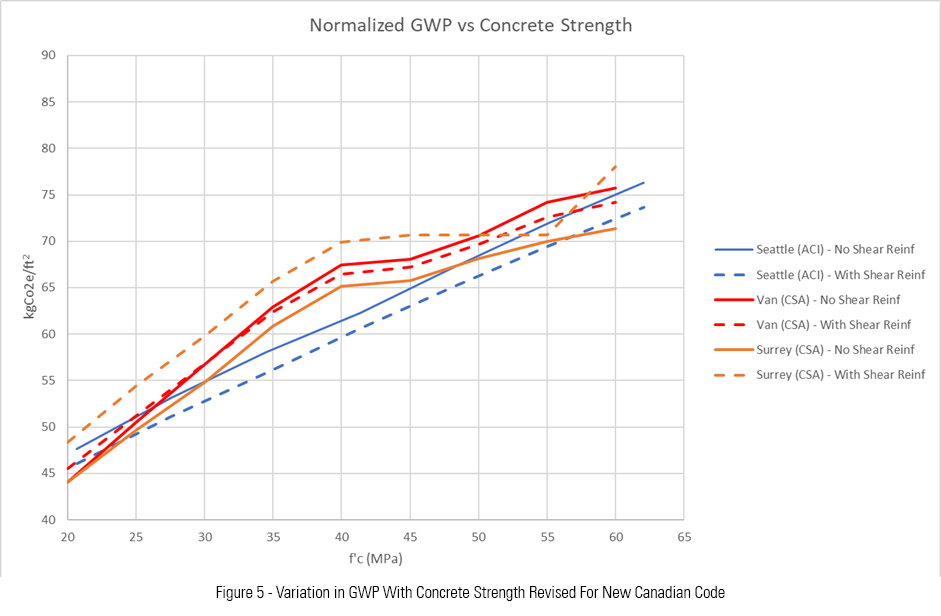

The studies were done by adjusting one variable at a time (i.e. concrete strength) under the same footing load. To better understand the impact of each variable, independent of the soil condition, the plots are normalized by the footing plan area. Generally good soil conditions will result in smaller footings and lower GWP.

From the results shown below, the initial design conclusions, based on the parameters noted above are as follows:

1. Pad footings with lower concrete strength will provide lower GWP as shown in Figure 4.

2. Use of shear reinforcing provides reductions in GWP for pad footing designs under both the Canadian and American codes; however, this reduction is much more significant under the Canadian code as shown in Figure 5.

How Does This Affect the Construction Budget?

How Does This Affect the Construction Budget?

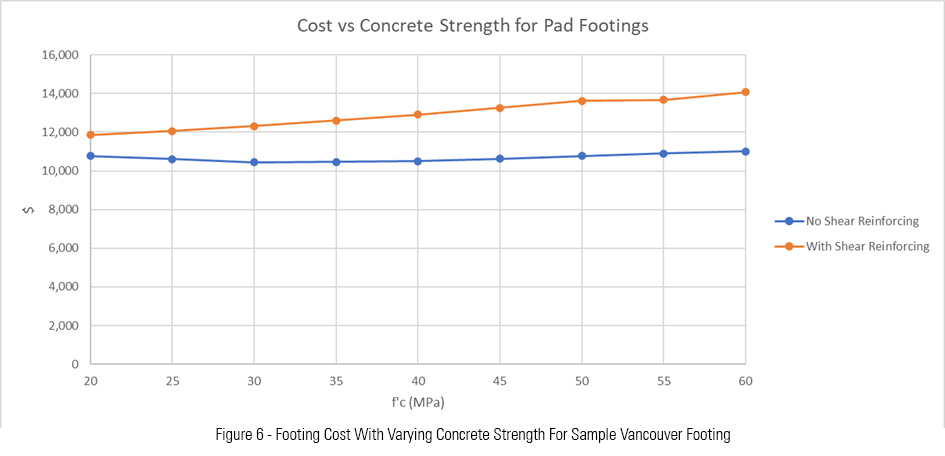

We recognize cost is always a factor. Our studies show that low concrete strengths with no shear reinforcing provide the most cost-effective solution. Below is a comparative plot showing the cost of footings at varying concrete strengths, with and without shear reinforcement, for a sample footing design in Downtown Vancouver.

Based on the various parametric studies, it is immediately clear, from both a cost and GWP perspective, pad footings should be designed with the minimum concrete strength permissible by code.

Based on the various parametric studies, it is immediately clear, from both a cost and GWP perspective, pad footings should be designed with the minimum concrete strength permissible by code.

Since shear reinforcing offers a minimal reduction in GWP, we do not feel this reduction is worth the reduced constructability and cost premiums – best to leave them out. Sometimes, the way it’s always been done is the right way after all… although, it’s great to have ample data to back that up!

What Else Can We Do To Reduce Embodied Carbon?

On a high-rise tower, it could be a year or longer before the footings at the base are required to resist the full load. Therefore, switching from a 28-day to 56-day mix should have no impact on the construction schedule and results in reductions on average of 5-10 kgCOe/m3 for concrete with high levels of supplementary cementitious materials (material that replaces some of the cement in concrete). Given the large volume of concrete in typical footing elements and the number of footings throughout the building floor plate, this savings in GWP can be significant.

Interested in sustainable building design and how we can help reduce embodied carbon in complex structural designs? Get in touch with us at info@GlotmanSimpson.com

Written by Marcus Monk

Glotman Simpson’s On Track series delves into factors we can explore to reduce the environmental impact of building structures. The need to accelerate climate action in the form of innovative solutions that minimize both operational and embodied carbon is imperative and represents a critical part of a low-carbon future.